The boardroom was immaculate, the kind of place where every surface gleamed and every chair looked too expensive to sit in comfortably. Floor-to-ceiling windows overlooked the city skyline, a reminder of power, progress, and money. Around the long polished table sat executives in tailored suits, laptops open, coffee cups untouched. At the head of the table was the CEO, confident, sharp-tongued, and used to being the smartest person in every room.

The meeting was supposed to be routine. A discussion about delays in the company’s logistics division had stretched longer than expected, and frustration was beginning to show. Charts were projected onto the screen, filled with red arrows and missed deadlines. Someone mentioned a persistent mechanical issue in one of the company’s largest distribution centers—an aging system that kept failing and costing thousands of dollars per hour.

The CEO leaned back in his chair, smirked, and let out a short laugh. “What do we need,” he said loudly, “a miracle or a grease-stained mechanic with a wrench from the Stone Age?” A few executives chuckled politely. Others exchanged uncomfortable glances. The joke landed, but not cleanly.

What the CEO didn’t realize was that the meeting room door was slightly open.

Standing just outside was a mechanic named Daniel. He had been called in that morning to assess the same system being discussed, after weeks of failed fixes by outside consultants and expensive contractors. Daniel was in his late forties, wearing worn work boots, oil-stained coveralls, and carrying a battered toolbox that looked older than some of the executives in the room.

He heard the joke. Every word of it.

Daniel didn’t react. He didn’t get angry or defensive. He simply adjusted his grip on the toolbox and waited. Years in workshops and factory floors had taught him something valuable: results speak louder than pride.

A few minutes later, a junior manager stepped out, spotted Daniel, and waved him in. “You’re the mechanic, right? The CEO wants an update.”

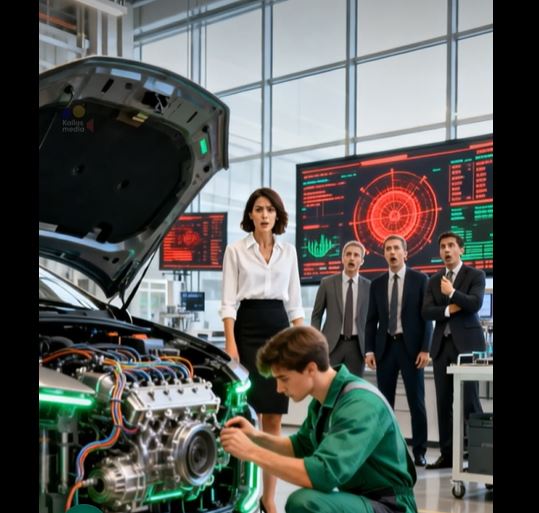

Daniel walked into the boardroom, suddenly the most out-of-place person there. Conversations stopped. Eyes followed him as he crossed the polished floor, his boots leaving faint marks no one dared to comment on. The CEO glanced at him briefly, his expression unreadable.

“So,” the CEO said, folding his hands, “you’ve seen the problem. Can you fix it?”

Daniel nodded calmly. “Yes.”

There was a pause. One executive raised an eyebrow. Another leaned forward. The CEO tilted his head slightly. “We’ve had three engineering firms look at it,” he said. “Millions spent. Weeks lost. And you’re telling me you can fix it?”

Daniel didn’t waste time explaining theories or throwing around jargon. He asked for access to the facility, requested one assistant, and a four-hour window where no one would interfere. The CEO waved his hand dismissively. “Fine. But if this doesn’t work, we’re done here.”

Down in the distribution center, surrounded by deafening machinery and blinking warning lights, Daniel came alive. He moved with purpose, listening to the sounds others ignored, feeling vibrations through metal surfaces, watching patterns in the system’s behavior. While previous teams had relied on software diagnostics and reports, Daniel relied on experience—decades of it.

He shut the system down completely, something no one else had dared to do. Supervisors panicked. Phones rang. But Daniel remained calm. He dismantled a critical component piece by piece, discovering a flaw so simple it was almost embarrassing: a misaligned part installed years earlier during a rushed upgrade. It caused cascading stress, triggering failures that no patch or update could fix.

Within hours, he corrected the alignment, reinforced a worn joint, and restarted the system.

The machines roared back to life—smoothly, efficiently, quietly. No alarms. No error codes. The system ran better than it had in years.

By the time the CEO arrived on the floor, arms crossed and skepticism intact, the distribution center was fully operational. Packages moved seamlessly. Workers stood around in disbelief.

Engineers reviewed the data. Metrics improved instantly. Downtime dropped to zero. Costs stabilized. What months of meetings and millions of dollars hadn’t solved, one mechanic had resolved in an afternoon.

Word of what happened spread quickly through the company. The joke the CEO had made became a lesson retold in meetings and training sessions. Not as a story of embarrassment, but as a reminder: expertise doesn’t always wear a suit, and intelligence isn’t measured by job titles.

Daniel returned to his workshop the next day, toolbox in hand, boots still worn. Nothing about him looked different. But everything had changed. His phone rang more often. His opinion was sought. His work was respected.